Why SnapCor

-

✓ Works with any thermal camera

-

✓ Instant on-site reporting

-

✓ Trusted by industry experts

Powered by TICOR – field-tested across 10+ years of inspections

Frequently Asked Questions

Quick answers to the most common questions about SnapCor.

1. What is SnapCor?

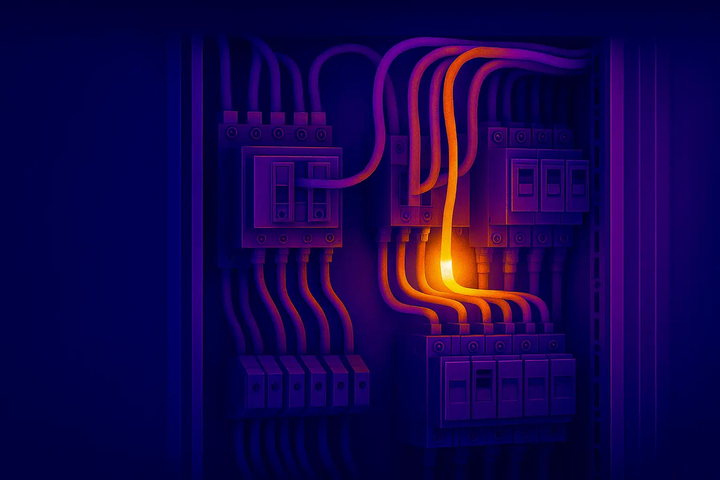

SnapCor is a thermographic inspection reporting platform that turns thermal and visual images into fully formatted, professional PDF reports in under 60 seconds. It is designed specifically for electrical thermography and building envelope inspections, automating data entry, load correction, fault grading, and report layout so thermographers can deliver client-ready reports directly from the field.

2. Who is SnapCor for?

SnapCor is built for anyone who needs to produce high-quality thermal imaging reports at scale, including:

- Thermographers and infrared consultants

- Electrical maintenance and reliability engineers

- Facilities management and FM providers

- Data centre operators and critical power teams

- Oil & gas, utilities, manufacturing, and industrial plants

Whether you’re a solo inspector or an enterprise with multi-site operations, SnapCor helps standardise thermographic reporting across your organisation.

3. What problems does SnapCor solve vs manual reports?

Traditional thermography reporting often relies on Excel, Word templates, or camera vendor software. These workflows are slow, inconsistent, and hard to standardise across teams.

SnapCor solves this by:

- Automating report layout and formatting

- Applying BS7671-compliant load and temperature correction automatically

- Standardising fault grading (Minor, Important, Serious, Critical)

- Embedding thermal & visual images, data tables, and trending graphs into a single PDF

- Generating reports on-site without needing a laptop or office-based software.

The result: less time formatting, more time inspecting and advising clients.

4. Is SnapCor a cloud platform, a mobile app, or both?

SnapCor is an offline-first, hybrid system:

- On-device app running on Android (tablet and mobile) and Windows devices for field data capture and instant report generation

- Optional central system (WebCor) for syncing reports, trending across multiple sites, and enterprise-wide analytics.

You can work entirely offline during inspections, then sync data securely when you’re back online.

5. What types of inspections can I do with SnapCor?

SnapCor supports both electrical thermography and building envelope surveys, including:

- LV & HV electrical panels

- MCCs, switchboards, ACBs, contactors, isolators, UPS systems

- Motors, generators, control panels, transformers

- Cable terminations, busbars, distribution boards

- Building envelope inspections (insulation defects, thermal leaks, air infiltration, cladding, moisture ingress)

6. How quickly can SnapCor generate a report?

SnapCor is engineered for speed. A typical 50-image electrical thermography report can be generated in under 60 seconds once the data is captured and graded in the app.

Because the fault pages, tables, and images are automatically laid out, thermographers can deliver ISO-aligned, client-ready PDFs before they leave the site.

7. Does SnapCor work offline on site?

Yes. SnapCor is designed as an offline-first thermography reporting app:

- All inspection data is stored locally on the device

- Reports can be generated and exported without an internet connection

- When a connection is available, reports can be synced to the central WebCor system or exported to your CMMS/BMS.

This is ideal for remote sites, substations, plants, and data centres where connectivity is limited.

8. What kind of reports does SnapCor produce?

SnapCor generates fully formatted PDF thermography reports that typically include:

- Executive summary and asset inventory

- Fault pages with thermal & visual images

- Temperature and load data tables

- Fault grading (Minor / Important / Serious / Critical)

- BS7671-compliant load/temperature correction data

- Trending graphs comparing current vs previous inspections

- Work orders and remedial recommendations

These reports are designed to be ISO 18436-7-aligned and audit-ready for clients and regulators.

9. How does SnapCor handle fault grading and severity?

SnapCor uses a built-in fault grading system to classify each anomaly as Minor, Important, Serious, or Critical. This grading is based on temperature rise, load conditions, and risk to asset integrity or safety.

By standardising severity levels across your thermography team, SnapCor supports consistent, risk-based maintenance decisions and makes it easy for clients to prioritise remedial work.

10. Does SnapCor support trending and condition monitoring?

Yes. SnapCor can track temperature and load data for each asset over time, enabling:

- Trending graphs for recurring inspections

- Comparison between current and historical thermographic surveys

- Identification of slow-developing faults and degradation patterns

This turns thermographic inspections into a powerful condition monitoring and predictive maintenance tool.

11. Can SnapCor automatically perform BS 7671 load & temperature correction?

Yes. For electrical thermography, SnapCor includes automatic load correction and temperature rise calculations aligned with BS7671 cable temperature references.

This means inspectors don’t need to manually calculate corrected temperatures or look up reference tables—the app embeds compliant values directly into the report, reducing error and improving traceability.

12. Does SnapCor use AI? How?

SnapCor uses AI and rule-based logic to accelerate reporting while keeping the thermographer in control:

- AI-assisted annotation of faults and anomalies

- Intelligent defect classification and suggested severity

- Auto-generated remedial recommendations from a standardised root-cause library

- Validation of temperature data and load inputs

You still make the final call, but SnapCor removes repetitive typing and helps keep language consistent across all reports.

13. Can I customise report templates and fields in SnapCor?

Yes. SnapCor supports configurable report templates and input fields, especially in Pro and Enterprise tiers:

- Custom fields for site, asset, and client information

- Optional sections for specific industries (e.g., data centres, O&G, FM)

- Branding with your company logo and colour scheme (Pro/Enterprise)

- Flexible work order and remedial sections

This allows you to align SnapCor output with your internal standards or client requirements.

14. Which thermal cameras does SnapCor support?

SnapCor is camera-agnostic and works with any thermal camera that can export images in standard formats. It has been tested with:

- FLIR (including radiometric IS2 files)

- Fotric

- Workswell

- Hikmicro

- Guide Sensmart

- InfraTec

If your camera can export JPG, PNG, TIFF, or compatible radiometric files, it can typically be used with SnapCor.

15. Which devices and operating systems does SnapCor run on?

SnapCor is optimised for:

- Android tablets and mobiles (Android 10+; 7" screen or larger recommended, 10" preferred)

- Windows 10/11 tablets or laptops (for certain deployments)

Minimum recommended specs:

- Quad-core 2.0 GHz processor or better

- 4 GB RAM minimum (8 GB recommended)

- 64 GB storage (128 GB recommended for heavy users)

- 8+ hours of battery life for field use

16. What file formats can SnapCor import and export?

Import:

- Thermal & visual images: JPG, PNG, TIFF

- FLIR radiometric: .IS2

- Data imports: CSV, JSON (for advanced integrations)

Export:

- Fully formatted PDF reports (primary deliverable)

- Structured data via JSON/CSV for CMMS, BMS, DCS, or other analytics tools.

17. Can SnapCor integrate with my CMMS, asset management, or BMS/DCS system?

Yes. SnapCor Enterprise supports integration with:

- CMMS (Computerised Maintenance Management Systems)

- Asset management platforms

- BMS/DCS systems via JSON or API

This allows thermographic inspection data and work orders to flow directly into your existing maintenance workflow, rather than living in standalone PDF reports.

18. What SnapCor licence options are available?

SnapCor offers flexible licensing designed to match your reporting volume and team size:

- SnapCor Lite – Single thermographer licence with core report generation

- SnapCor Pro – Higher report volumes, trending, load correction, advanced templates, multi-project management

- SnapCor Enterprise – Unlimited users/reports, WebCor integration, API access, white labelling, multi-site analytics, custom hosting.

Pricing and plan details are available on the SnapCor pricing page.

19. Can I start small and scale SnapCor as my team grows?

Absolutely. Many users start with SnapCor Lite or Pro on a single tablet and later upgrade to an Enterprise deployment as their inspection workload grows, or they add more thermographers.

Because SnapCor’s workflow is the same at all tiers, scaling up doesn’t require retraining your team—only enabling more licenses and features.

20. Is SnapCor suitable for data centre electrical thermography?

Yes. SnapCor is ideal for data centres and critical power environments, where fast, consistent, and defensible reports are essential:

- Electrical panels, UPS, PDU, switchgear, and busbars

- BS7671-aligned load correction for high-current circuits

- Fault grading that supports risk-based maintenance

- Trending across repeated inspections on critical assets

Data centre teams can demonstrate due diligence and build a defensible thermal inspection history for audits and compliance.

21. Can I use SnapCor for building envelope and insulation inspections?

Yes. While SnapCor is optimised for electrical thermography, it also supports building envelope inspections:

- Insulation defects

- Thermal bridges and air leaks

- Cladding and façade issues

- Moisture ingress patterns

Custom templates allow you to capture building-specific observations while still benefiting from SnapCor’s fast reporting workflow.

22. Are SnapCor reports compliant with thermography and electrical standards?

SnapCor is designed to support compliance with key standards and best practices, including:

- ISO 18436-7 – Condition monitoring and diagnostics; thermography reporting

- BS7671 – Electrical installation requirements (cable temperature/load correction)

- NFPA 70B – Electrical equipment maintenance and thermography guidance

- ISO 9712 / ASNT SNT-TC-1A – Supports tracking of certified thermography personnel

While final responsibility for inspection practice remains with the user, SnapCor helps ensure reports contain the data and structure needed for compliance and audit defence.

23. How does SnapCor handle data security and GDPR?

Security and data protection are core design principles for SnapCor:

- Encrypted local storage on devices

- Authenticated, secure sync to central servers over HTTPS

- GDPR and UK Data Protection Act–compliant data handling

- Role-based access control (Enterprise)

- Audit trail of report changes and user actions

This makes SnapCor suitable for organisations with strict IT, cybersecurity, and compliance requirements.

24. Does SnapCor keep an audit trail and calibration information?

Yes. SnapCor Enterprise can maintain:

- Audit trails of report edits, status changes, and user activity

- Calibration tracking for supported thermal cameras (e.g., FLIR), helping document that your inspection data is based on calibrated equipment

This is valuable for regulated industries, insurance disputes, or internal quality assurance.

25. How many inspections can I store on one device?

Storage depends on image size and device capacity, but typical field deployments support 500+ inspections per device before archiving or syncing is required.

Because SnapCor stores structured data plus images, using recommended 128 GB devices gives plenty of room for multi-year inspection histories.

26. How long does it take to get my team up and running?

SnapCor is designed with an inspection-led interface that mirrors existing fault pages and work order forms, so most thermographers can be productive after a short onboarding session.

SnapCor Product Brochure

Typical rollout steps:

- Install SnapCor on your chosen devices

- Import sample images and run through a test inspection

- Customise templates and branding (Pro/Enterprise)

- Train thermographers using built-in documentation and video tutorials

Many teams are fully operational within days rather than weeks.

27. What support and training does SnapCor provide?

Support options include:

- Online onboarding and configuration guidance

- User guides, video tutorials, and best-practice resources

- Email and chat support (priority support for Pro/Enterprise)

- Dedicated account management and SLA-backed support for Enterprise deployments

This ensures your thermography team can rely on SnapCor for mission-critical reporting.

28. How does SnapCor compare to camera vendor software like FLIR Thermal Studio?

Camera vendor software is typically tied to a specific manufacturer and often requires office-based processing. SnapCor takes a different approach:

- Works with any thermal camera (camera-agnostic)

- Designed for on-site use on tablets and mobiles

- Automates BS7671 load correction and ISO-aligned reporting

- Scales from single-user to multi-site enterprise deployments

Many users keep vendor tools for advanced image analysis but rely on SnapCor as their primary reporting and compliance platform.

29. Can I white-label SnapCor reports with my own branding?

Yes. SnapCor Pro supports custom-branded templates and removal of SnapCor watermarks, while Enterprise offers full white-labelling for large organisations and service providers.

You can include your logo, colours, and report formatting so clients see the thermography service as your branded deliverable.

30. How do I get started with SnapCor or request early access?

You can request early access or a demo directly via snapcor.app by submitting your details, or contact the team at TI Thermal Imaging / TICOR:

- Website: snapcor.app

- Email: info@ticor.co.uk or sales@thermalimaging.co.uk

- Phone: +44 (0) 203 089 3222

A member of the SnapCor team will discuss your use case, recommend the right licence (Lite, Pro, or Enterprise), and help you plan your deployment.

Apply for early access